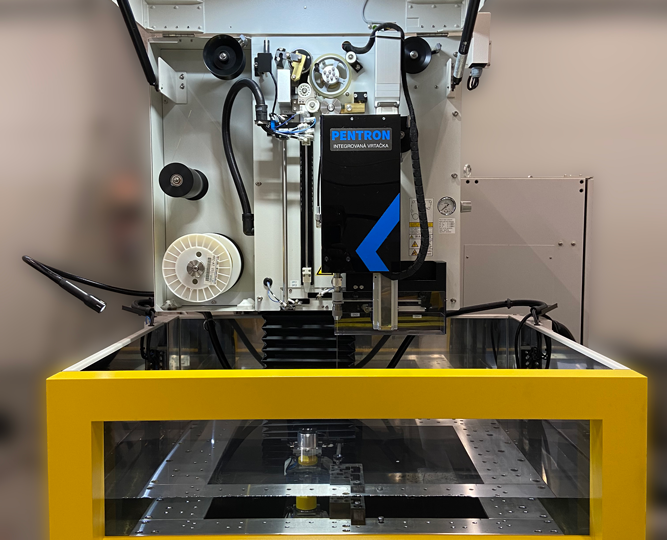

PENTRON – INTEGRATED START HOLE DRILLING FOR FANUC ROBOCUT

PENTRON is an integrated start hole drilling unit for FANUC ROBOCUT – Wire Electrical Discharge Machining (WEDM).

Integration means that postiton of holes and drilling itself is programmed and control by M51 function on FANUC wire EDM CNC driving system. PENTRON is developed and distributed by PENTA TRADING.

MAIN BENEFITS

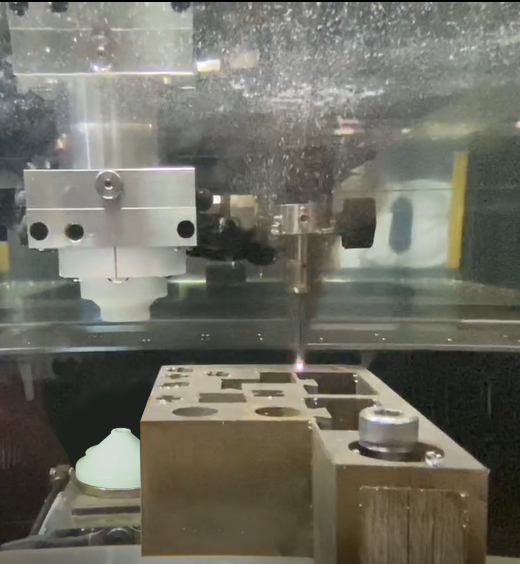

- Drilling Directly on W-EDM machine using M-code

- Do not need to re-setup work pieces on separate machine

- Easy operation – drill & cut

- Independent high presssure pump

- Full integration into wire EDM machine

- Floor space saving

- Unique compact design

- Easy installation

Technical data

| STANDARD | PENTRON |

| Axes stroke | |

| Z axes [mm] | 400 |

| Maxim jog speed mm/min] | 1 200 |

| Max. working depth [mm] | max. 150 |

| Rotation speed [rpm] | 240 |

| Drilling chuck size [mm] | 0,3 ~ 3,0 |

| PENTRON CNC | |

| Axes under control | Z |

| Min. step [mm] | 0,001 |

| Control | Driven by FANUC macro |

| Remote button control included | |

| Unit diagnostic | Remote desktop, status LEDs |